In the beginning, there were viruses and corporate partnerships.

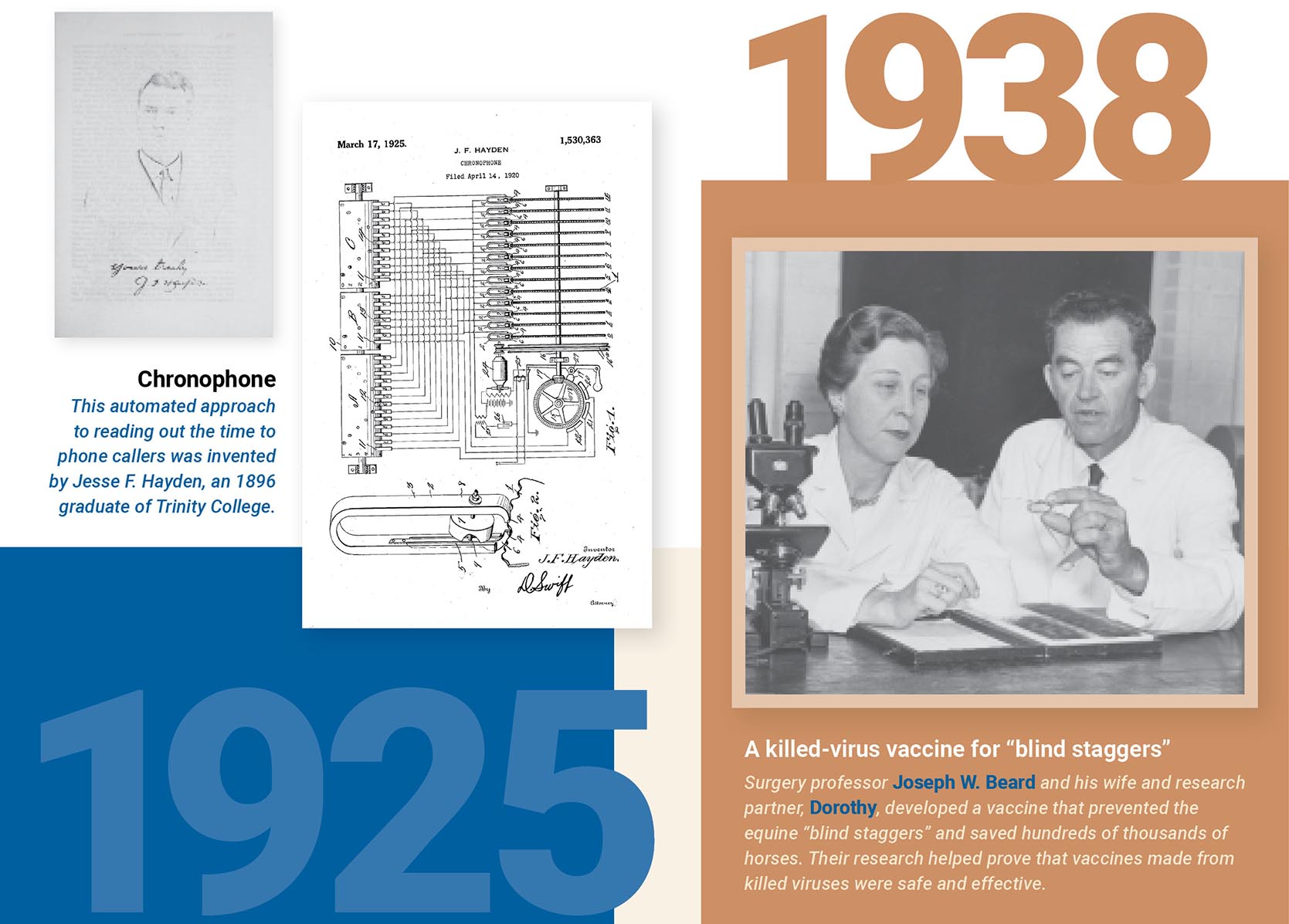

As Duke University Medical Center rose in Durham in the 1930s, a relatively new infection called equine encephalomyelitis was devastating American horses. The “blind staggers” struck 800,000 animals per year, many of which died or were permanently lamed.

You’ve never of heard of equine encephalomyelitis because it was conquered by a husband-and-wife team of Duke researchers. Their success in 1937 led to the university’s first dedicated research fund and its first purpose-built medical research facility. This was the foundation of all that was to follow.

Lederle Labs, a veterinary pharmaceutical company in New Jersey, had begun work on a vaccine as the new disease spread. But their process required infecting horses, killing them, harvesting their brains, applying formalin to kill the virus and then extracting a tiny amount of vaccine from the slurry. It was not a great model for industrial-scale solutions. The company turned for help to newly arrived Duke virus and cancer researchers Joseph and Dorothy Beard. Lederle supported Joe Beard’s salary at Duke and provided the researchers with a $6,500, two-year grant.

The Beards incubated viruses in chicken eggs, hit them with diluted formaldehyde, gave them a whirl in a centrifuge, and then filtered out killed virus particles that were not infectious but were capable of building immunity. This was the first commercially successful killed-virus vaccine, making it a forerunner of Jonas Salk’s polio vaccine, and Lederle sold 1.3 million doses of it in 1938. By the time the Beards’ vaccine patent expired in 1958, it had earned $300,000 in royalties.

This provided a new problem for Duke to solve: What to do with the profits from commercially successful academic research?

In agreement with the Beards, the Lederle royalties were used to establish the Dorothy Beard Research Fund, which supported research and provided nearly a third of the $750,000 to build the medical center’s first dedicated research building. The building soon housed one of the world’s first electron microscopes, a gift from American Cyanamid, Lederle’s parent company.

The first U.S. patent assigned to Duke University itself came in 1945. Marine Lab Director Harold Judson Humm, a botanist, had found a way to extract a gelatinous substance called gelosefrom red algae. The goo was useful for all sorts of gummy jobs and today it’s called carrageenan. You can find it on food labels as a stabilizer of products that might otherwise separate.

Duke’s Gross Hall isn’t named for its 1960s brutalist architecture, but rather for Paul M. Gross, chemistry chair and campus leader from 1919 to 1960. Gross was a serial inventor and solver of practical problems. As America geared up to enter World War II, pilots in training needed to practice shooting down enemy planes without actually hurting anyone. Gross’ previous two patents were related to the cigarette business, but he got to work on this challenge and whipped up a frangible bullet, one which fired and flew like real ammo, but shattered harmlessly on impact with a plane. Student pilots fired off an estimated 13 million rounds of Gross’s bullet and nobody got hurt.

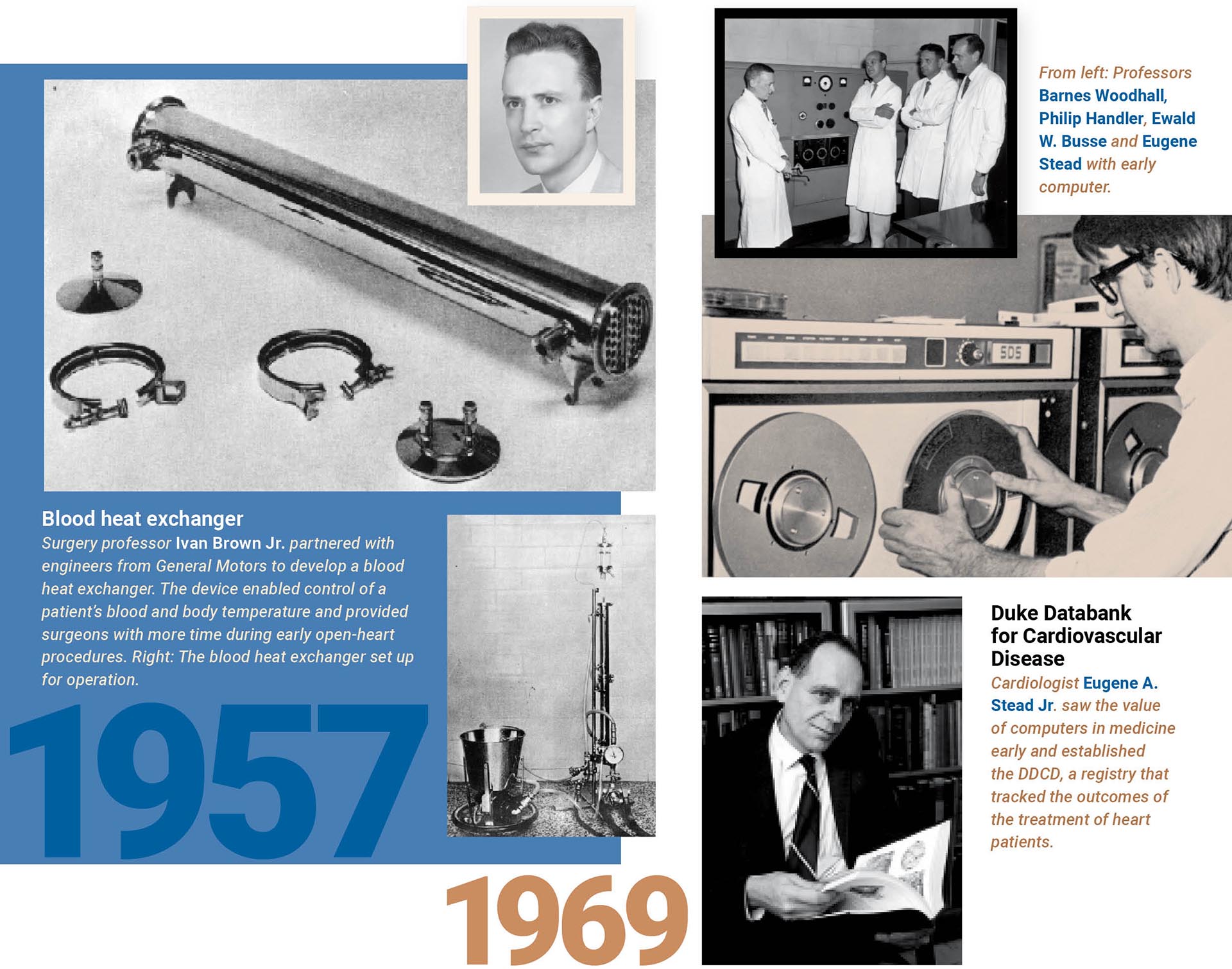

By 1957 corporate partnership was back in play with the invention that became a precursor to modern heart-lung machines. Surgery professor Ivan Brown Jr., a co-developer of blood banking and an expert in transfusion, got help from radiator engineers at General Motors to build the first blood heat exchanger.Thisglass cylinder filled with circular radiator fins was used to precisely control a patient’s blood and body temperature during Brown’s pioneering open heart surgeries. The machine made the procedures less rushed and a lot more successful. Duke’s medical library still holds an early version of the device that saw action in Brown’s OR.

Today, one of the things Duke Medicine is best known for around the world is its prominence in clinical trials. Duke has led the nation for more than two decades in the amount of research funding received from industry, a great majority of which is because of the gleaming Duke Clinical Research Institute in downtown Durham. This research colossus grew out of visionary cardiologist Eugene Stead’s ability to see the newfangled computers of the 1960s as a possible tool for better medicine. In 1969, Stead established the Duke Databank for Cardiovascular Disease, building a computerized registry of the treatment of heart patients and how it all turned out – an early version of today’s clinical trials. We take for granted today that hidden patterns can be extracted from a huge database, but without computers, that kind of global vision simply wasn’t possible. The more data Stead collected, the more powerful the tool became. Stead’s vision was such that he and Medical School Dean William Anlyan took the trouble to persuade the College of Arts and Sciences to establish a training program in computer science in 1973 to create more workers for this promising new technology. Computer science is now Duke’s largest undergraduate major.

Duke’s biomedical engineers didn’t invent ultrasound for medical imaging, they merely made it spectacularly powerful. To assess a beating heart’s function, a static, two-dimensional ultrasound image isn’t much help. You need depth of field and, ideally, motion. Duke engineers Olaf von Ramm and Stephen Smith provided that capability by creating what is now marketed as 3D and 4D ultrasound. A Japanese team had been first to create a three-dimensional image from ultrasound in the mid-1980s, but the images weren’t as sharp as 2D and the machine was too slow to be practical in clinic. After seven years of work on building better probes and co-developing new computer chips that could handle the processing load, von Ramm and Smith’s team at Duke introduced a precise and speedy 3D ultrasound in 1994.

As we zoom off into the future, Duke researchers are being awarded more than 100 new patents each year. One of the brightest paths is being blazed by technology called “metamaterials.” Duke physicists and engineers, led by David R. Smith of electrical and computer engineering, are creating satellite receivers that don’t need a dish, walls that passively scan passengers for weapons, cellular signals that grow stronger where and when they are needed, and much more. Metamaterials are devices that, through their physical shapes and not necessarily their materials, bend the rules of all sorts of waves, including energy, radio, light and sound. They might be 3D printed in some cases, or made with the same affordable technology that produces television screens – it all depends on what kinds of waves you want to bend.

At last count, more than 10 new companies had spun out of Duke’s metamaterials research, many of them led by Duke alumni. You will be seeing these Duke-spawned metamaterials in your daily life very soon, though more likely, you won’t be aware of them at all.